Spread ProcessingPRODUCT

Two strengths of spread processing

Preservability

Shelf life

precote® has a shelf life of four years, which is longer than other products.

This product can be stored for a long period as inventory, helping reduce waste and cost.

Convenience

Supporting tip processing

Our spread processing equipment can perform tip processing for each thread. In addition, no additional cost is required even for spread processing for tips.

Furthermore, our equipment supports detailed specifications for spread processing for threads.

Product Lineup

LOCTITE®

Earth-friendly water-soluble loose stopping and sealing agents widely used around the world.

We also offer a lineup of earth-friendly water-soluble loose stopping coatings and sealing agents.

- Sealing agents

- Shelf life of one year

F-LOCK®

Repeatable, adhesive-free nylon-based loose stopper.

This product is an adhesive-free, non-reactive loose stopper. It can be used repeatedly and offers excellent maintainability.

- Nylon

resin - Semi-permanent

shelf life - Repeatable

precote®

A shelf life of four years! European-standard spread processing for a variety of applications.

A shelf life of four years! European-standard spread processing supporting applications for anti-loosening, liquid leakage prevention, baking prevention, and underhead seals.

- Adhesive

- Shelf life of four years

NYCOTE®

Recognized worldwide as masking agents for threads for product cost reduction and efficiency increase

European-standard spread processing with masking processing for protecting threads from welding spatters and electrodeposition coating.

- Protection

from spatters - Coating protection

About reactive (fixed-type) and non-reactive pre-coating

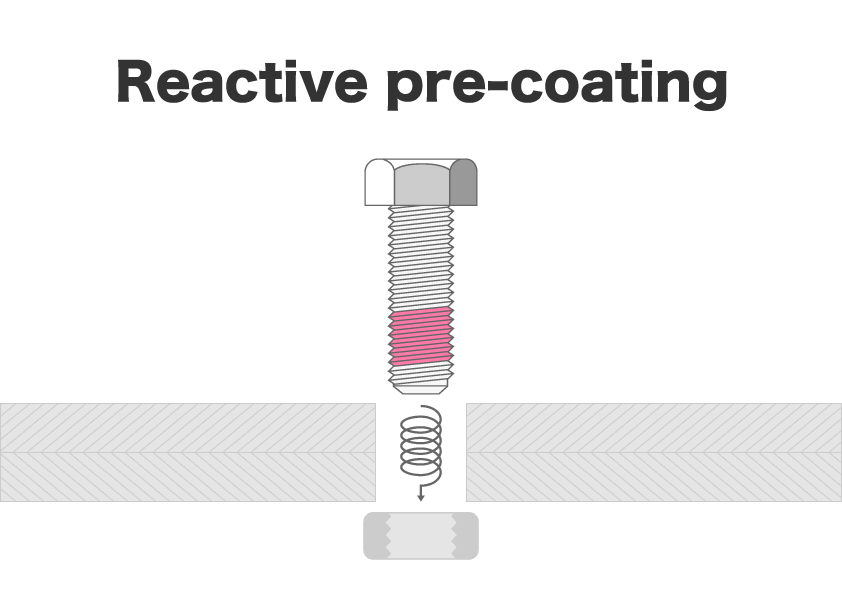

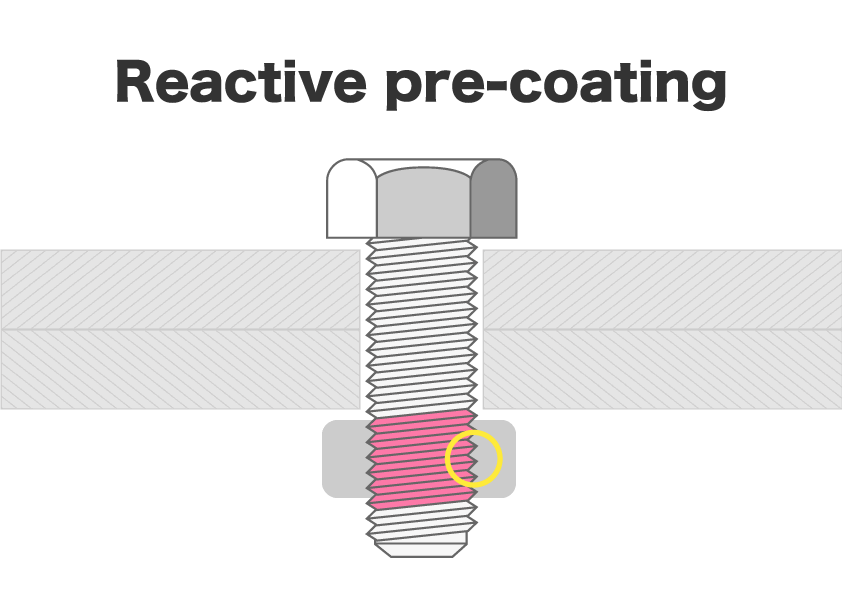

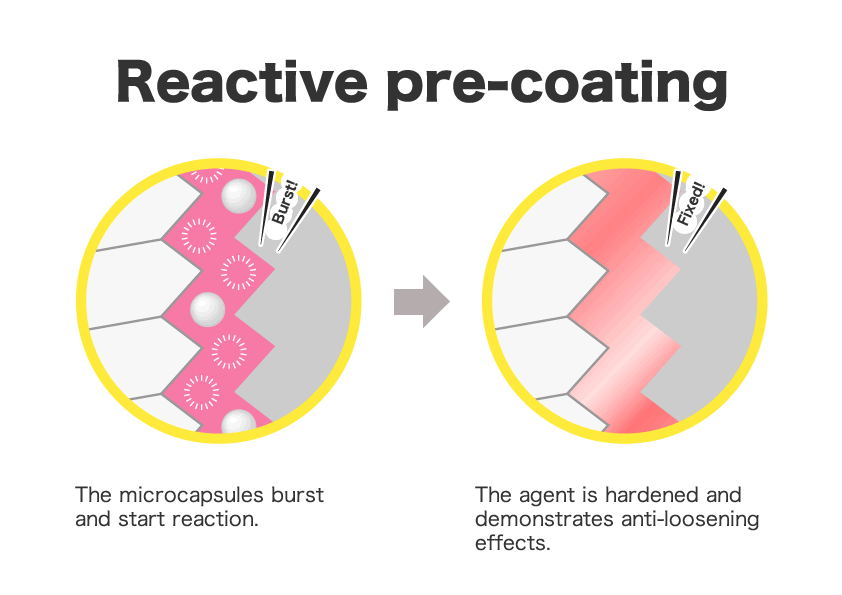

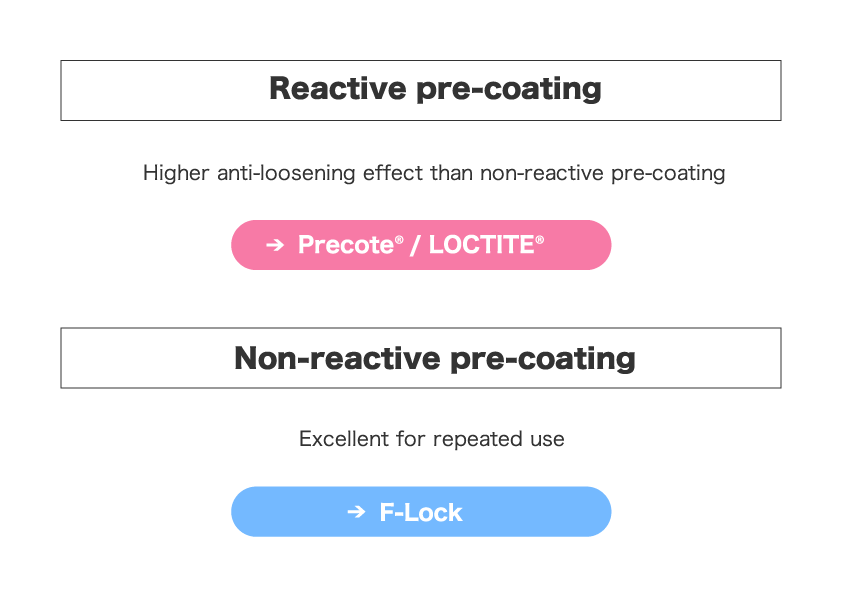

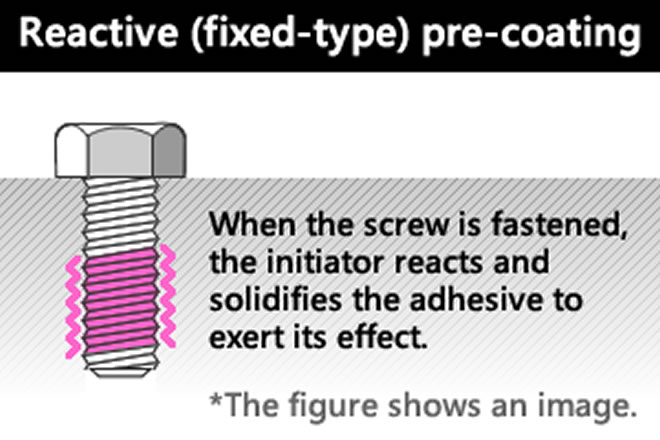

Reactive (fixed-type) pre-coating

When a screw is fastened, the adhesive begins to harden to fix it.

With this spread processing method, after the screw is fastened, the adhesive solidifies to fix it.

- Because the curing agent in the adhesive is microencapsulated, the part can be stored after the adhesive is applied and dried.

- The curing time after fastening needs to be taken into account. The curing time varies depending on the product.

- The loose stopping effect is excellent while the screw is being fixed, but the effect is lost after the occurrence of breakdown torque.

- Because the screw is fixed by adhesive, it cannot be reused once removed.

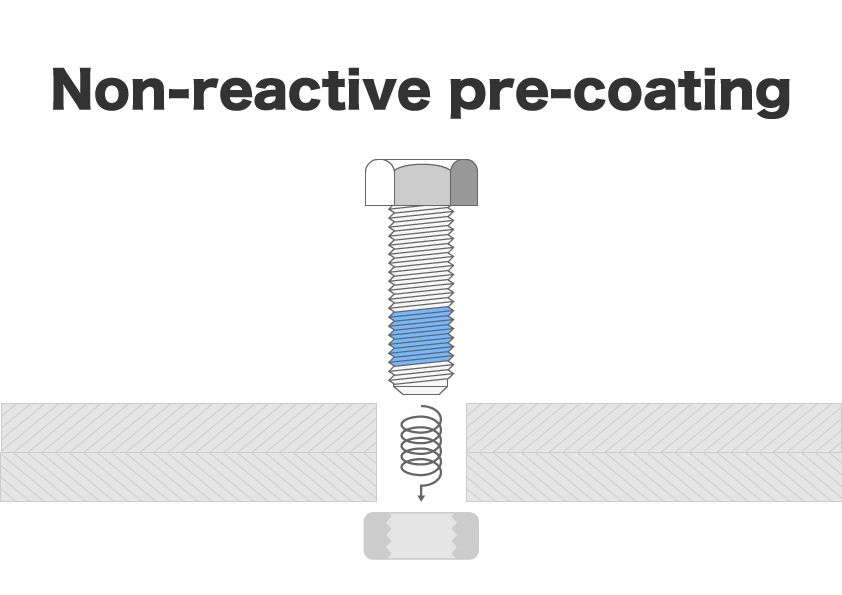

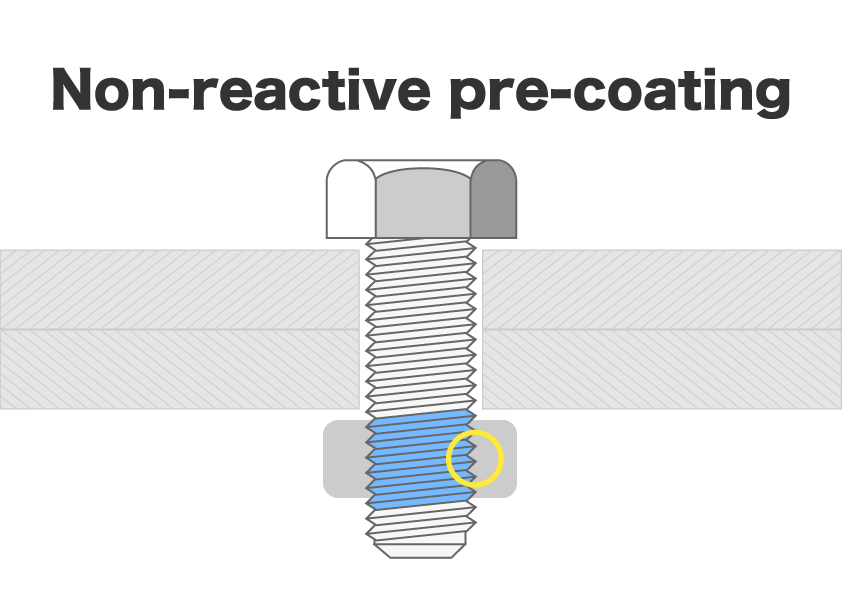

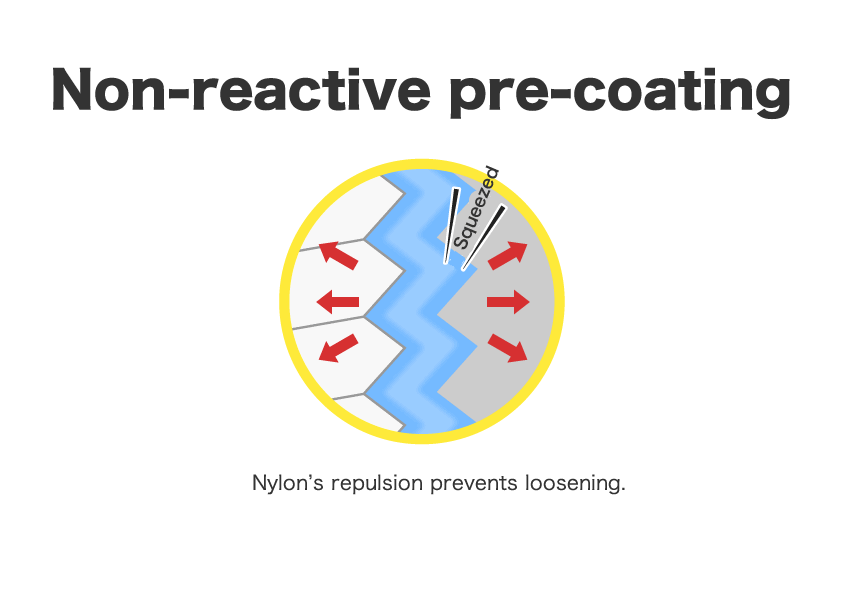

Non-reactive pre-coating

The non-reactive pre-coating has a variety of effects as well as an anti-loosening effect.

This spread processing method uses nylon resin, acrylic resin, and powder coating.

- It allows processing that demonstrates effects other than the anti-loosening effect, such as liquid leakage prevention, baking prevention, and masking of threads.

- The screw can be used repeatedly because the nylon resin loose stopper (F-LOCK®) does not harden.

- The effect is demonstrated as soon as the screw is fastened.

- This type of pre-coating has a longer shelf life and higher preserving property than the reactive one.

Differences between reactive and non-reactive pre-coating

RoHS Directives and REACH Regulations

All of our spread processes comply with the RoHS Directives and REACH Regulations, which restrict the use of certain hazardous substances in the European Union (EU).

Please feel free to contact us for safety and technical information.

The EMANAK Group has obtained ISO 9001 and ISO 14001 certifications at all of its manufacturing sites.