Metal Thermal TreatmentPRODUCT

Carburizing

Enabling carburizing thermal treatment of steel tapping screws and precision equipment screws.

Production of tapping screws and precision equipment screws, which is in rapid demand,

requires advanced technology and skilled process control.

We consider and propose the optimal treatment based on the data,

such as steel materials and mated materials, presented by our customers.

Carburizing thermal treatment of tapping screws with excellent plating processes

Carburizing thermal treatment hardens the steel surface and maintains the inner viscosity.

Carburizing thermal treatment refers simply to a thermal treatment that hardens the steel surface and maintains the inner viscosity. Carburizing thermal processing turns the surface into high-carbon martensite with hardness similar to that of tool steel and turns the center into low-carbon martensite with rich toughness. This processing is mainly suitable for tapping screws.

Are you worried that carburized products are hard to plate?

Our carburizing thermal treatment has been highly evaluated for its excellent plating performance. Do you know why our carburized products are evaluated as having excellent plating performance, despite usually being considered difficult to plate?The secret lies in the thermal treatment with our know-how accumulated over many years.

Pre-cleaning

Before processing, the product is cleaned to remove any oil adhered during manufacturing processes.

Intermediate cleaning

After quenching and cooling, the product is cleaned again to remove the cooling oil.

We place particular emphasis on the cleaning process and have a reputation for the beauty of processed products and the plating quality. Please feel free to consult us if you find any appearance or plating problems after carburizing thermal treatment is performed. We receive inquiries not only from screw manufacturers but also from surface treatment companies.

Simple flow of the carburizing thermal treatment process

- 1Pre-cleaning

- 2Quenching

- 3Intermediate cleaning

- 4Tempering

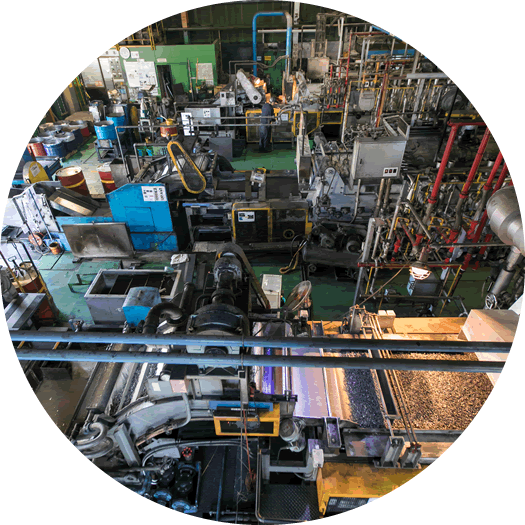

We use a continuous furnace manufactured by Toyo-Ro Industries Co., Ltd.

For a continuous gas quenching and tempering furnace for carburizing, we use a continuous furnace manufactured by Toyo-Ro Industries Co., Ltd. The combination of our unique know-how and highly reliable treatment equipment ensures that the finished products are always reliable for our customers.

Carburizing thermal treatment of precision equipment screws

Consult with us about No. 0 screws, camera screws, and micro screws.

We are capable of carburizing thermal treatment of No. 0 screws and camera screws (M0.6 to M2.6) as well as micro screws (M2 or less), which are classified as precision equipment screws.

Our Yashio Manufacturing Division (located in Yashio-shi, Saitama) handles the carburizing thermal treatment of precision equipment screws.Please feel free to contact us.

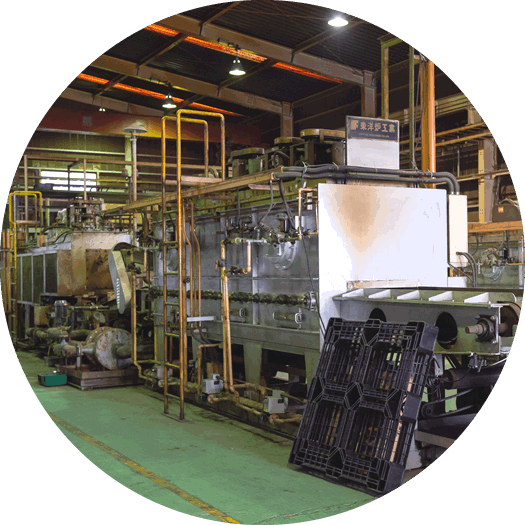

For a furnace for precision parts, we also use a product manufactured by Toyo-Ro Industries Co., Ltd.

For a continuous gas quenching and tempering furnace for carburizing precision parts, we use a product manufactured by Toyo-Ro Industries Co., Ltd.

Major certified companies

Toyota Motor Corporation, Nissan Motor Corporation, Honda Motor Co., Ltd., Mazda Corporation, and others

Contact the following for consultations and inquiries about carburizing.

Responsible personnel: Tarutani

Tanaka Nekko Co., Ltd.

Moriguchi Plant (Carburizing)

4-24-8 Minamiterakatahigashidori, Moriguchi-shi, Osaka 570-0043 Japan

Responsible personnel: Setoguchi

EMANAK EAST JAPAN Co., Ltd.

Yashio Plant

606-1 Kizone, Yashio-shi, Saitama 340-0813 Japan

Click here to download the metal thermal treatment and carburizing brochure.