Surface TreatmentPRODUCT

Three powers of surface treatment

Ability to make proposal

Support from the development stage

It is our specialty to support manufacturers from the product development stage. We offer a wide range of optimum proposals that combine thermal treatment, surface treatment, and spread processing to prevent product problems in the design stage. These unique proposals are the most welcomed by our customers. Please feel free to contact us.

Ability to solve problems

Contact us for any difficulties.

You may experience problems, such as failure to obtain the product specification expected in the design stage while the cause is unknown. The more complex the factors, the more difficult it is to find the cause. In such a case, please contact us. We can help you with a wide range of solutions, including thermal treatment, surface treatment, and spread processing.

Ability to respond

A wide range of product lineups

We offer a wide range of lineups for foundation, base coats, and top coats.

You can receive a variety of proposals for surface treatment simply by consulting with us.

We offer various options to achieve the optimal functionality you need.

Product Lineup

Top Coat

PLUS Series

Gives new properties to anti-corrosion surface treatment.

Dedicated water-based chromium-free overcoat that enhances GEOMET® performance.

- Chromium-free

- High corrosion resistance

- Stable friction coefficient

ECOAT® WH Treatment

Enhances corrosion resistance, chemical resistance, and the ability to prevent contact corrosion between different metals.

Overcoat applied on DACROTIZED® and GEOMET® to enhance corrosion resistance, chemical resistance, and galvanic corrosion prevention.

- Chromium-free

- High corrosion resistance

- Chemical resistance

- Galvanic corrosion prevention

Base Coat

GEOMET®

Provides a completely chromium-free, environmentally friendly water-based anti-corrosion treatment.

A completely chromium-free water-based anti-corrosion treatment that enables further consideration of the environment based on the DACROTIZED® technology.

- Chromium-free

- Corrosion resistance

Foundation

Mechanical Coating (EMALUCE)

Performs cold dry plating capable of enhancing the corrosion resistance of high-strength bolts and castings.

Cold dry plating that forms a zinc alloy film having higher corrosion resistance and optimum for anti-corrosion treatment of high-strength bolts, sintered parts, and castings.

- Dry plating

- No hydrogen embrittlement

- Nonferrous

functional improvement

WPC

The treatment improves fatigue strength, prevents wear due to lack of lubricants, and improves strength by alloying metal surfaces.

- Machine Parts

- Cutting Tools

- and Dies

We offer a wide range of products.

- Foundation

- Material

- Mechanical

- Plating

- Base Coat

- GEOMET®

- GEOMET Pro 100

- UNIMET

- C Coat

- Top Coat

- PLUS Series

- ECOAT® WH Treatment

- #10

- #50W

- UNIMET

- Mechanical + UNIMET = UZ Coat

- Mechanical + C Coat = CZ Coat

We propose the best combination!

We propose the best surface treatment to meet your requirements (performance and cost).

Please feel free to contact us from the product development stage. Our staff will propose solutions.

Mega solar

For long-term outdoor use

For many years of use in outdoor exposure conditions, it is necessary to prevent contact corrosion between different metals with aluminum frames. We therefore proposed the design that withstands further aging degradation by plating the foundation for high corrosion resistance of the original GEOMET®.

- Foundation

Plating - Base Coat

GEOMET®

Play equipment (water sliders)

Preventing corrosion from repeated wet drying

We responded to the request for preventing corrosion due to scratches in the harshest environment for repeated exposure to water and drying.

- Foundation

Mechanical Coat - Base Coat

UNIMET

Anchor bolts

Reducing corrosion from construction scratches

Adopted as fence installation anchors for public facilities in Okinawa. Mechanical coating is used for the foundation to reduce construction scratches.

- Foundation

Mechanical Coat - Base Coat

GEOMET®

Automobiles

Realizing designability

Used for mounting bolts for automotive body exterior parts in harsh environments for repeated exposure to water and drying. Also, black design is required for the exterior parts. We therefore proposed a special coating method.

- Foundation

Mechanical Coat - Base Coat

UNIMET - Top Coat

UNIMET

Outdoor units

For long-term outdoor use

Used in outdoor exposure for many years. GEOMET® is applied to the alloy plating to further improve corrosion resistance.

- Foundation

Plating - Base Coat

GEOMET® - Top Coat

PLUS Series

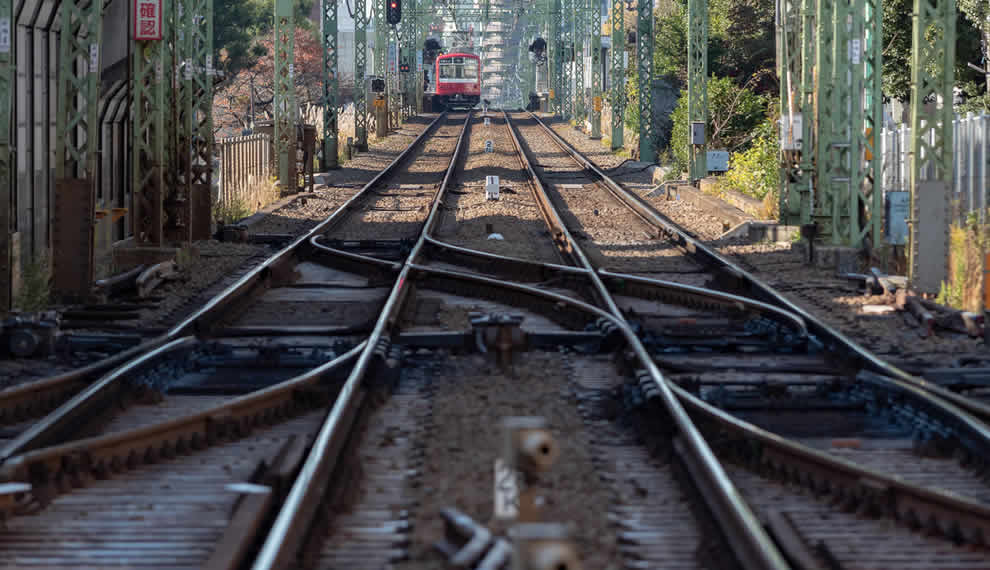

Rails

Protecting rails from rust caused by iron powder

It was necessary to have sufficient corrosion resistance to withstand rust caused by iron powder dropped from vehicles.

- Foundation

Mechanical Coat - Base Coat

C Coat

Automobiles

High quality standards

We support each car manufacturer’s specified coating amount by offering various types of top coats.

- Foundation

GEOMET® - Base Coat

PLUS Series

Vehicles

Achieving optimal tightening torque

We proposed the best top coat for fastening parts mainly used for connecting parts of vehicles, considering the optimal tightening torque.

- Foundation

GEOMET® - Base Coat

PLUS Series

The EMANAK Group has obtained ISO 9001 and ISO 14001 certifications at all of its manufacturing sites.