Surface TreatmentPRODUCT

Mechanical Coating

(EMALUCE)

Dry plating at room temperature with the capability to

improve the corrosion resistance of high-strength bolts and castings

- Dry plating

- No hydrogen embrittlement

- Supports

nonferrous

materials

Plating processes are often referred to as "wet plating" because the surface is treated with a liquid agent. Mechanical Coating(EMALUCE), however, differs greatly from other plating processes in that it uses dry plating without a liquid agent.

Not only does the Mechanical Coatingeliminate the risk of stress reduction due to heat and hydrogen embrittlement, but it also provides a high-level anti-corrosion effect for products, such as high-strength bolts and castings, that were difficult to plate.

Try this for products that are difficult to plate.

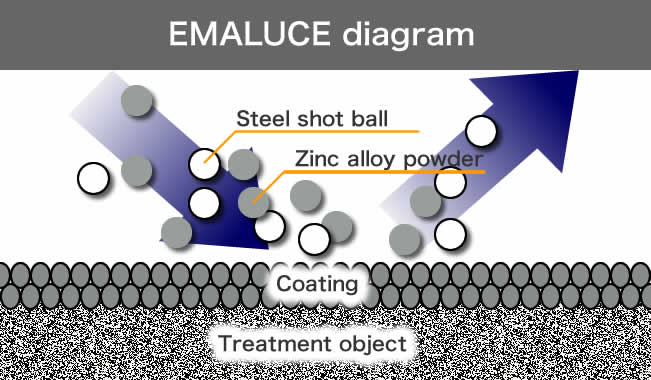

Mechanism of Mechanical Coating(EMALUCE)

A zinc alloy coating is formed by shot peening

The iron-zinc alloy powder is sprayed onto the surface material at high speed to form the zinc alloy coating. The mechanical coating has been certified as an anti-corrosion surface treatment for automotive parts and is capable of treating both ferrous and nonferrous materials.

Six features of Mechanical Coating(EMALUCE)

Point1

Point1

Capable of treating

both ferrous and nonferrous materials

Point2

Point2

No stress reduction due to heat

thanks to dry plating at room temperature

Point3

Point3

Less of acid treatment and electrolytic reactions, which result in no hydrogen embrittlement

Point4

Point4

No sealing required for the sintered parts

Point5

Point5

Mechanical properties improved from the peening effect

Point6

Point6

Environment-friendly surface treatment on the process line because of no drainage

The application of a conventional coating (metal flake type or others)

or organic-inorganic hybrid coating

after applying Mechanical Coating(EMALUCE) achieves high corrosion resistance.

Processing parts suitable for EMALUCE

Particularly suitable for high-tension parts, such as fasteners (bolts, nuts, brackets, and tapping screws), chains, springs, and sintered parts.

Application fields of EMALUCE processed products

Automobiles (mainly outdoor parts), civil engineering projects (bridges, ports, railways, and nuclear power plants), and buildings (trusses)

The Mechanical Coatingis, for example, effective as a lubricant base for the plastic processing of cold forged parts.

- SUS, titanium, etc.

can also be processed to

provide corrosion

resistance. - Reduction of plastic

processing pressure

enables longer life of dies. - This method is also friendly

to the construction period and

environment because the process is

short and generates

no drainage.

Contact the following for consultations and inquiries about Mechanical Coating (EMALUCE)

We propose the optimal surface treatment for you.

Please feel free to contact us.

- 1We have the know-how and experience to propose the optimal combination of surface treatments according to the operating environment, corrosion resistance, and cost.

- 2We offer a wide range of lineups for foundations, base coats, and top coats to meet your needs.

Responsible personnel:: kamino

EMANAK WEST JAPAN Co., Ltd.

Kadoma Plant

26-3 Yanagidacho, Kadoma-shi, Osaka 571-0038 Japan

Click the link below to download the brochure for Mechanical Coating(EMALUCE)

Fill in the form below. We will send our catalog information to the e-mail address provided by you. (If you do not have a company name or a department name, enter "None".)