Surface TreatmentPRODUCT

WPC Treatment®

Precision Shot Peening

(Machine Parts, Cutting Tools, and Dies)

Enables surface treatment and thermal treatment of metal products effective for extending the life of machine parts, cutting tools, and dies.

What is WPC Treatment®?

About the name

WPC is an abbreviation

Wide Peening and Cleaning

or

Wonder Process Craft

Technologies and effects

WPC Treatment® has three effects of surface modification technologies.

- Thermal treatment effect

- Formation of micro-dimples

(matte finish) - Cementation

plating

WPC Treatment® mainly improves the strength and function of machine parts, cutting tools, and dies.

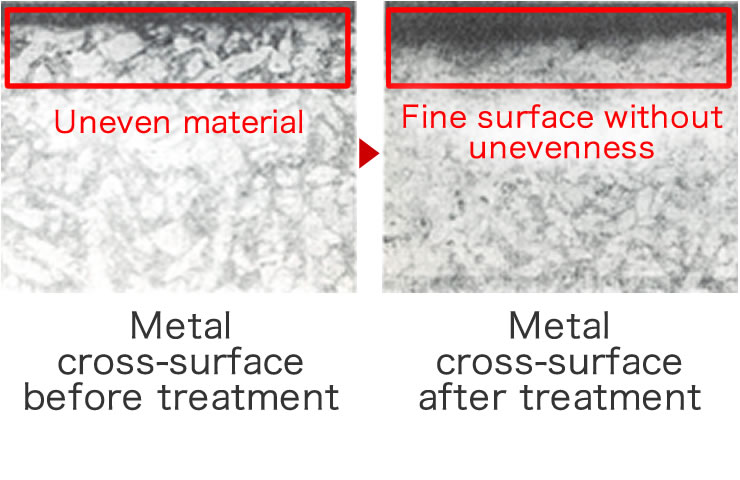

Thermal treatment effect

This treatment greatly improves fatigue strength by eliminating uneven metal surfaces and by applying internal residual compressive stress.

The surface treatment and thermal treatment method of WPC Treatment® strengthens the processing of thermal treatment and forging effects. The retained austenite in the metal surface layer is transformed into martensite, recrystallized, and refined, resulting in a dense, high-hardness, high-toughness structure. Also, a significant life extension can be expected because of the increase in the internal residual compressive stress of the surface.

This method is suitable for the following types of steel:

●SCM material (chrome molybdenum steel) ●SUJ material (bearing steel) ●SK material (carbon tool steel) ●SNCM material (nickel chromium molybdenum steel) ●SKD material (die steel) ●SKH material (high speed steel) ●CU material (cooper) ●SUS304 cermet material hard metal

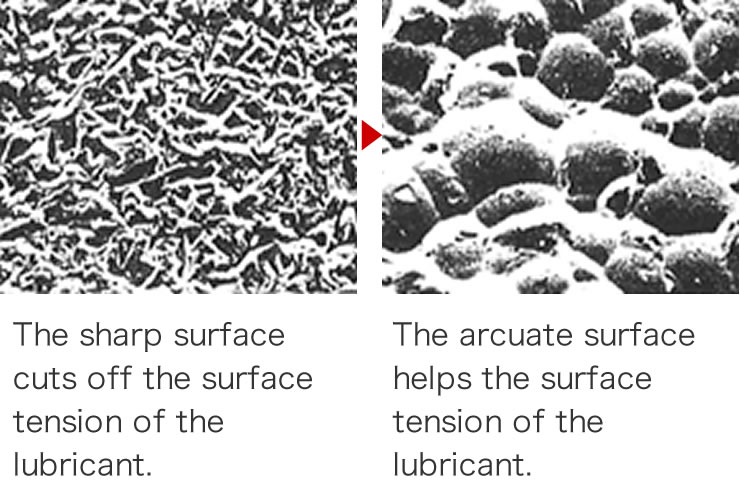

Micro-dimple effect

This treatment forms micro-dimple surface texture to prevent wear due to lack of lubricant.

The wear prevention method for sliding part of metal products (UPS) (EP) of the WPC Treatment® prevents wear due to lack of lubricants by forming micro-dimples (matte finish) on the surface of cut, abrasive, and shaved products, and improves the adhesion of various coatings due to increased surface area. Making an almost non-contact condition reduces gear noise, prevents baking, and controls oil temperature rise to extend the service life.

This method is suitable for the following types of steel:

●SCM material ●SUJ material ●SK material ●SNCM material ●SKD material ●SKH material ●CU material ●SUS304 material

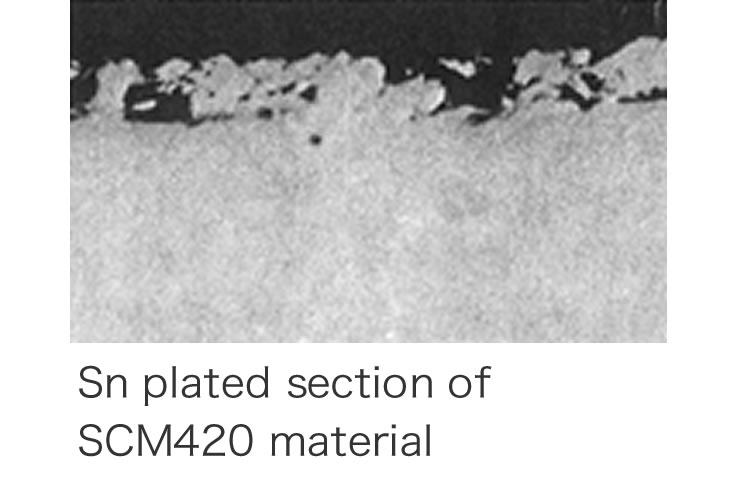

Cementation plating effect

This treatment alloys the metal surface to increase the strength.

The normal temperature cementation plating method of the WPC Treatment® alloys and strengthens the material surface by spraying metal powder suitable for each purpose to diffuse and impregnate the surface with the constituent elements. Adhesion strength can be increased by using this method as a base treatment for plating and coating, and dry plating at room temperature is also possible by spraying metal powder with a low melting point and low hardness.

This method is suitable for the following types of steel:

●SCM material ●SKD material ●SKH material ●PVD material ●Die casting material

WPC Treatment® is effective for machine parts, cutting tools, and dies.

Effects on machine parts

| Improvement of fatigue strength | Improvement of surface hardness |

| Improvement of impact resistance | Improvement of adhesion to coating |

| Improvement of sliding properties | Prevention of cold brittleness |

| Improvement of corrosion resistance | Prevention of various types of corrosion |

Item examples

| Pistons | Gears |

| Shafts | Metals |

| Pins | Springs |

| Wheels | Connecting rods |

Effects on cutting tools

| Improvement of wear resistance | Reduction of cutting resistance |

| Improvement of chipping resistance | Improvement of surface hardness |

| Improvement of adhesion to coating |

Item examples

| Drills | End mills |

| Taps | Reamers |

| Broaches | Hobs |

| Tip saws | Metal saws |

Effects on dies

| Improvement of fatigue strength | Improvement of wear resistance |

| Improvement of material flowability | Improvement of material release properties |

| Improvement of adhesion to coating | Reduction of heat checks |

Item examples

| Cold dies | Hot dies |

| Die casting dies | Drawing dies |

| Press punches | Rolling dies |

| Rubber dies | Resin dies |

| Header punches |

Effective for removing fine burrs and scales.

In addition to the effects of the improvement of fatigue strength, prevention of wear, and improvement of strength by alloying the surface, we can offer various types of WPC Treatment®, such as fine deburring, scale removal, and beauty treatments, by applying the effect of precision shot peening, so please feel free to contact us.

We can also offer comprehensive proposals for various types of metal thermal treatment and WPC Treatment®.

We can perform not only carburizing (quenching and tempering) and thermal refining (quenching and tempering) but also vacuum thermal treatment for stainless steel or for dies and tools. For example, we can combine WPC Treatment® with various types of metal thermal treatments for materials, such as SKH materials (high speed steel) and SKD materials (die steel) requiring vacuum quenching, as well as SCM materials (chrome molybdenum steel) requiring thermal refining.

We conduct sample treatment of dies for performance comparison.

Please verify the effects of WPC Treatment® at your production site!

We will conduct sample treatment of your dies.

Verify the effects of extending the life of dies through WPC Treatment using your production equipment.

Contact the following contact for details.

Contact the following for consultations and inquiries about WPC Treatment®.

Responsible personnel:Koshino

EMANAK WEST JAPAN Co., Ltd.

Moriguchi Plant (WPC Treatment®)

4-24-12 Minamiterakatahigashidori, Moriguchi-shi, Osaka 570-0043 Japan

Click here to download the WPC Treatment® brochure.

*WPC Treatment® is a registered trademark of Fuji Kihan Co., Ltd., Fuji Manufacturing Co., Ltd., and Fuji WPC Co., Ltd.