Metal Thermal TreatmentPRODUCT

Vacuum Thermal Treatment

Enables various types of vacuum thermal treatment suitable for small mass-produced products and precision parts as well as screws.

Vacuum nitriding treatment of SUS410 tapping screws and drill screws

Screwing performance equivalent to that of steel screws is added to tapping screws and drill screws.

Vacuum nitriding treatment (bright quenching) is characterized by performing quenching in a special atmosphere to diffuse and harden nitrogen while maintaining the brilliance of the screw surface. Vacuum nitriding treatment achieves a surface hardness of around Hv600 and a nitriding depth of 200 microns.

We were the first in the industry to put vacuum nitriding treatment into practical use and have been highly evaluated.

There are currently many competitors in the same industry that perform vacuum nitriding treatment, but we were the first in the industry to develop and commercialize the vacuum nitriding treatment by applying the patented technology (at that time) we developed jointly with a vacuum furnace manufacturer over 30 years ago. We have been highly evaluated by evolving our know-how of the time to continue to meet customer needs.

[Major steel materials suitable]

Martensitic stainless steel (such as SUS410, SUS403, and SUS420J2)

*Please feel free to contact us for any unlisted steel grade.

Vacuum quenching of small mass-produced products and precision parts

For example, micro screws for weak electricity can also be thermal-treated.

Vacuum quenching (bright quenching) is a thermal treatment suitable for martensitic stainless steel. Our facilities are ready to accept large quantities of small mass-produced products and precision parts. Please feel free to contact us.

[Major steel materials suitable]

Martensitic stainless steel (such as SUS410, SUS403, and SUS420J2)

*Please feel free to contact us for any unlisted steel grade.

Solution thermal treatment

This treatment prevents the generation of deposits and cracks.

Solution thermal treatment is suitable for austenitic stainless steel. The treatment prevents not only corrosion resistance degradation due to deposits but also cracks generated after riveting.

[Major steel materials suitable]

Austenitic stainless steel (such as SUS303, SUS304, and XM7)

*Please feel free to contact us for any unlisted steel grade.

Vacuum thermal-treated products that are not properly tempered may lack toughness.

Needless to say, the surface of stainless steel hardens when it is quenched. However, it is difficult to know whether tempering is performed properly by measuring the surface hardness after tempering.

If tempering is not performed properly, it may cause poor toughness, increasing the risk of fracture or flying-off of part heads during use.

Our vacuum thermal treatment equipment performs integrated processing from quenching to tempering. We provide stable and reliable services in terms of quality.

Our integrated processing ensures proper treatment from quenching to tempering. Please feel free to contact us!

Simple flow of the vacuum thermal treatment process

- 1Degreasing

- 2Quenching and heating

- 3Cooling

- 4Tempering

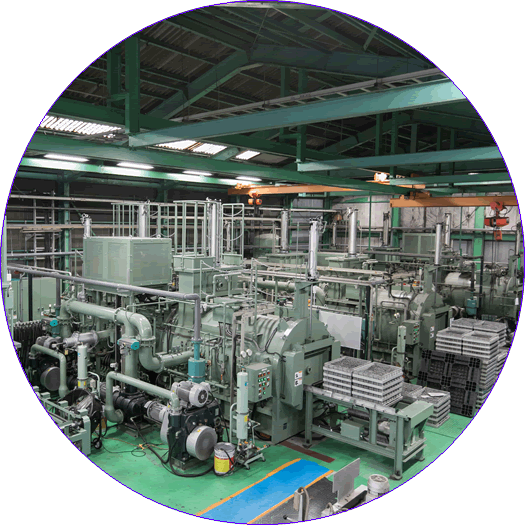

We have installed four state-of-the-art three-chamber vacuum furnaces to achieve both technological and production capabilities.

The vacuum thermal treatment of stainless steel not only suppresses film degradation and decarburization of the processed product but also controls its hardness, characterized by excellent brightness and beautiful finish. Our equipment is the world’s most reliable vacuum furnace manufactured under license by Ishikawajima-Harima Heavy Industries Co., Ltd. (IHI)

We perform not only vacuum quenching but also various types of thermal treatment.

Annealing

Precipitation hardening treatment

-

Stress relief annealing

Spheroidizing

Low-temperature annealing

Softening

Various types of annealing - Precipitation hardening treatment is available mainly for SUS630.

Major certified companies

Toyota Motor Corporation, Nissan Motor Corporation, Honda Motor Co., Ltd., Mazda Corporation, and others

Contact the following for consultations and inquiries about vacuum thermal treatment.

Responsible personnel:kawamoto

Tanaka Nekko Co., Ltd.

Moriguchi Plant (Stainless Steel)

4-24-12 Minamiterakatahigashidori, Moriguchi-shi, Osaka 570-0043 Japan

Click here to download the vacuum thermal treatment brochure.